Options for hinges with a closer to furniture, and their features

Furniture accessories are presented in a wide range, characterized by high quality and advanced mechanisms. To install the doors during cabinet assembly of products, furniture hinges with a closer are used, equipped with internal shock absorbers for smooth closing of doors. Accessories have a different configuration, size and type of execution, is widely used in the manufacture of cabinet furniture.

Features

The main difference between furniture hinges with a closer is a silent and smooth closing of the door leaves. Each product is equipped with an auxiliary device (closer or shock absorber), which allows you to fix the furniture facade to the body accurately, without slamming. In the body of the loop is a spring filled with oil, gas or a viscous medium. Depending on the type of loop overlay, the fittings can be overhead, half-laid, internal execution. Unconditional advantages of a design with a closer:

- silent and smooth closing of doors. A little effort is enough to ensure that the sash closes neatly. In this case, the door does not hit the furniture body;

- increase the life of the furniture. It is impossible to slam a door equipped with a closer, which prevents mechanical damage to the canvas;

- The furniture can withstand significant loads, so massive facades can be installed on furniture products. The closer is reliably fixed inside the loop with screws or latches;

- The hinge mechanism can be adjusted to fit the door snugly against the body. No professional tools required for adjustment;

- the filling of the cylinder with the spring is isolated by a fuse against oil or working fluid leakage, therefore, when the hinge fails, the mixture does not fall onto the furniture.

By adjusting the closing valves, the closing speed of the furniture doors is increased or decreased. With a little effort (just enough to push the sash), the door closes under its own weight. The liquid covering the spring, when closing the doors, flows into the sleeve of the closer capsule. The narrowing (expansion) of the channel of the outflow of fluid causes the movement of the piston. The valve adjustment sets the speed of the piston element and controls the time the doors are completely closed.

Materials of manufacture

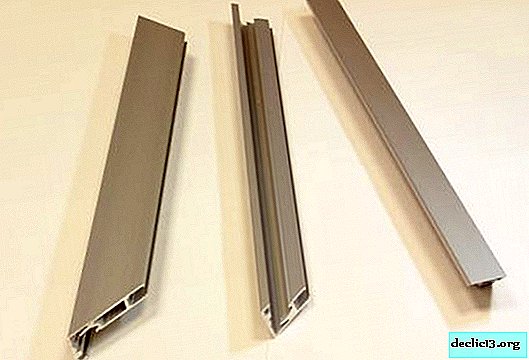

Quality fittings for opening / closing furniture doors, mainly made of cold rolled steel. The loop with the closer can have a lock. For its manufacture, a durable alloy of zinc, copper and aluminum is used. To increase the anticorrosive properties of the material, surface brass plating is used. For decorative purposes, loops with a closer are coated with enamels imitating bronze, chrome, nickel, and gold. The main elements of the loop are:

- platform for mounting on the housing;

- reciprocal level with a cup or an overlay for a facade;

- movable hinges with a spring mechanism;

- integrated type damper (built-in);

- shock absorber as an additional option (non-built).

Depending on the purpose, the hinges with closers can have a different structure and composition of the materials from which the accessories are made. For glass doors, a hinge bowl is not provided, the work is provided by movable hinges with a spring mechanism, there is an additional lining (o-ring) made of synthetic material. The world-famous hinge manufacturers use high-quality steel of increased strength for the manufacture of fastening accessories, so the service life of the products is measured over the years.

Each manufacturer indicates guaranteed cycles of opening / closing doors on hinges with closers.

What are they suitable for?

Hinges with closers are widely used in the manufacture of cabinet furniture for household, office and commercial purposes. Thanks to the self-closing mechanism, it is possible to avoid damage to the facades, which is especially important with frequent use of furniture. Hinges with a reason are used in the manufacture of the following furniture structures:

- bedroom sets - wardrobes, facades of dressing tables and chests of drawers. For sliding wardrobes and walk-in closets, sliding systems with closers are used, for drawers - meta-boxes;

- kitchen sets - wall cabinets and tables. With the help of hinges, it is convenient to close the upper and lower cases of furniture, with little or no effort;

- furniture for children's rooms and living rooms, desks for students. So that with frequent use of furniture the child does not slam the doors, it is worth equipping cabinets and tables with closers;

- office furniture - computer tables, shelving with doors for storing papers and documents. Employees of the company use furniture every day, it is important that it closes smoothly;

- trading groups - glass showcases. For the demonstration of goods under glass for commercial purposes, cabinets with glass display cases are installed. Hinges for furniture are mounted on an aluminum profile frame.

If you install a loop with a closer directly on a glass cloth with preliminary reaming, brittle material may not withstand frequent use. When enclosing glass in a metal frame, the installation of the loop will be more reliable.

How to choose

A wide range of hinges of various types of overlays, configurations and sizes is presented on the furniture hardware market. Hinges with a four-hinged overhead type closer with a mounting hole for a 35 mm bowl are considered standard. These are universal hinges used for the production of cabinet furniture. When choosing accessories, take into account the quality of products, filling the closer (gas is more economical, oil and silicone fluid - more reliable). Among the global manufacturers of loops recognized leaders are:

- Blum - are distinguished by three-dimensional adjustment of the facade in plane and space, equipped with a short mounting plate to simplify installation;

- Hettich - high quality materials and assembly of hinges and mechanisms with a damper. Differ in big service life, durability and reliable fixing;

- GTV - manufacturer's hinges show a good result in the durability and smoothness of the facade elements. Do not require complicated installation and adjustment;

- Boyard - products of a domestic manufacturer have conquered the market due to the high quality of hinges with a reason, a wide range of accessories and affordable products.

If the manufacturer does not indicate the product, you should not rely on the quality and reliability of such loops. An important indicator is the parameter declared by the manufacturer - the number of shutter open / close cycles. The optimal value is 60000-200000 times. The furniture owner can confidently open and close doors hung on hinges with an argument, every day, the spring mechanism will not fail.

Insert Stages

Installation of hinges of a laid on type with a closer is carried out by the method of inserting accessories. To work, you need a standard set of tools - a drill, screwdriver, level, cutter, ruler, pencil. For the installation of small elements, they are limited to one loop, but the installation of paired loops shows a higher reliability. The implementation of the work is as follows:

- marking of the door (facade) with the designation of the hinge mounting points. The optimum distance is 20 mm from the edge of the sash adjacent to the body. Indentation from the lower and upper edges - not more than 120 mm;

- when mounting three loops, the middle product is placed strictly in the center between the upper and lower loops. It is impossible to install accessories at the place where the hinge joins the furniture shelf or drawer;

- overhead loops with a closer are applied to the facade, circled along the contour of the looped bowl. In this place, a hole for a loop is made with a mill. Size varies by hinge manufacturer;

- drill holes for screws that secure the hinge plate and fix the hardware with fixing screws. Check the reliability of the installation;

- install the hinge on the furniture - in the closet, table, shelf. It is convenient to screw the pad with the horizontal position of the part. The central screw adjusts the hinged facade.

Fundamentally, the accessories scheme with different turning angles does not differ. The furniture hinge is screwed to the fixed body with a platform with a spring mechanism and a damper, and the facade is fixed strictly to the mounting plate.

Adjustment nuances

After fastening the hinge with the closer on the facade and the furniture body, the mechanism must be adjusted relative to the horizontal, vertical plane. Adjustment contributes to a more snug fit of the facade or its weakening to give the finished structure an attractive appearance, to obtain the same gaps between the parts. Subtleties of adjustment of loops with a damper:

- initially adjust the clearance vertically, then - in height. You should check the location of the furniture level in different planes, if necessary - adjust the legs. If the floors are uneven, it is not possible to perfectly set the furniture according to the level, the adjustment allows you to adjust the gap;

- conveniently adjust the hinges with a Phillips screwdriver. There are two screws on the furniture body. The screw closest to the edge rotates the leaf to the right and left. Adjust the upper and lower loops to obtain the desired result. Each screw is responsible for the diagonally opposite corner of the facade;

- To align the door in height, adjust the self-tapping screws on the furniture body. They need to be loosened (with a screwdriver or a screwdriver), set the facade to the required height, fix the screws. When working with a screwdriver, the nozzle is rotated at low speeds - the clamping of the self-tapping screw violates the door fixation strength;

- adjustment on the plane is necessary to prevent the formation of a gap between the door leaves and the body - the facade does not fit snugly against the furniture. To adjust, tighten the second bolt. If the upper edge of the facade does not fit, adjust the second bolt of the lower loop, if there is no plane from below, adjust the upper loop.

Hinges with closers allow you to perform three-dimensional adjustment of the facades - horizontal, vertical, frontal plane. Using the adjustment, you can hide the unevenness of the floor and walls - visually the facade on the table or wall cabinet will look perfectly flat.

The fittings are reasonably popular in the furniture industry, as they have high quality workmanship, long service life, and prevent mechanical damage to facades.